"JR1" (type35bugatti)

"JR1" (type35bugatti)

09/30/2016 at 07:45 ē Filed to: None

4

4

10

10

"JR1" (type35bugatti)

"JR1" (type35bugatti)

09/30/2016 at 07:45 ē Filed to: None |  4 4

|  10 10 |

Hope this mint green Cadillac brightens up your day!

Stapleface

> JR1

Stapleface

> JR1

09/30/2016 at 08:07 |

|

Gm was really killing it in the 50's. What a beautiful vehicle.

$kaycog

> JR1

$kaycog

> JR1

09/30/2016 at 09:09 |

|

Absolutely beautiful!

RamblinRover Luxury-Yacht

> JR1

RamblinRover Luxury-Yacht

> JR1

09/30/2016 at 09:50 |

|

Oh shit, look what I just found:

http://knoxville.craigslist.org/cto/5777536413.html

Nearly 4 hours from me, so actually getting and hauling them back would be a giant adventure, but wow.

Wheelerguy

> JR1

Wheelerguy

> JR1

09/30/2016 at 09:58 |

|

Another Cadillac that made my day was the announcement that theyíll reveal their DPi car this November at LA Auto Show. Which means DPi is in full swing. Which means IMSA is serious business again.

JR1

> RamblinRover Luxury-Yacht

JR1

> RamblinRover Luxury-Yacht

10/01/2016 at 18:18 |

|

That is a dangerous game sir. If you buy it youíd be a harbormaster with two massive yachts in the yard.

JR1

> Wheelerguy

JR1

> Wheelerguy

10/01/2016 at 18:19 |

|

I hadnít heard about that. Awesome. They have been making some great performance models lately.

RamblinRover Luxury-Yacht

> JR1

RamblinRover Luxury-Yacht

> JR1

10/03/2016 at 08:49 |

|

A fun note: I got under the Capri on Saturday to try to compare my CAD diagram of the sheet metal folds with reality. I was more wrong than I thought, but I should have enough info to get repair pieces made, now.

JR1

> RamblinRover Luxury-Yacht

JR1

> RamblinRover Luxury-Yacht

10/03/2016 at 15:04 |

|

Hey well at least you know now what needs to happen. Did you lift it with a floor jack or get the green monster on an actual lift?

RamblinRover Luxury-Yacht

> JR1

RamblinRover Luxury-Yacht

> JR1

10/03/2016 at 15:49 |

|

Well, itís on dry gravel in my car tent, and apart from the left front is on scrap tires that actually hold air, so itís just enough off the ground for me to reach things. By under, I do not actually mean my torso, just enough of my face and arm and such... although I have been properly under it a little bit before, because when we got it off the trailer we had it on some wood cribbing, and that was when I took the brakes apart.

It kind of *looms* when youíre under it. Extra sketchy.

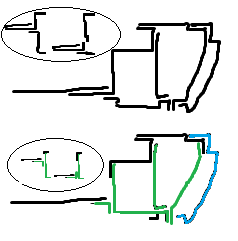

Iíve got the measurements to revise with, which I havenít done yet, but hereís a breakdown of what Iíve got to do. The original sheet metal is the first part, the repair is in the second part:

The blue part is the outer rocker. Curved, and the upper tab of it that connects to the rocker is only there where it passes through the door openings. Elsewhere, it just fuses to the door post, the front fender, the rear fender... Interestingly, this is the only piece you can buy new (!), though thatís a version for the two door. Whatís the difference?

As far as I know, the only difference is the length and the upper tab length - the two door would run longer in both,

but trimming it would be easy.

The panels are

so cheap

that I can get two sets, cut them to lengh, and seam them for less effort than trying to fold and cut pieces *and roll a curve into them, nearly 8' long*.Actually, that would allow me to repair the lower parts of the fenders *as well*. The curvature is correct, so I just cut off the ďtabĒ in a way that lets me do that.

So that part I buy and remake. The next layer in, I cut off close to the top and weld a piece in with... Iíve got it a little inaccurate there, it would have three bends. Just enough of a jog bend to attach the outer rocker to. The next piece in, I remove the spot welds holding it to the inner/top rocker, replace it completely with a single-folded piece. Done. The next piece, I trim it off, separating from the floor, and weld it in with plug welds - simple piece, has only two bends. Then, because the floor has some holing close to the edge and goes up and down, use an angle as shown to attach the floor, in as many pieces to match the curve as possible.

Whatís in the ovals in the Paint drawing, you might be wondering? Well, the left in each case is what the rocker does in the front of the floorboards- the floor rises up to blend into the torque box, and the rocker sort of comes out of it. Ludicrously complicated metal stampings, both the inner rocker and the bottom of the rocker have to change as it goes along, which is not good for a fix. On the right in the ovals is what it does under the door posts and next to the seat box. There, and only there, the rocker becomes ďtallerĒ to match with the structure sticking down about 3/4 of an inch lower. For the whole rest of the rocker panel, the rocker is stamped ďupĒ to the same height as the floor. This is utterly insane.

For the same strength (or more) as a beam structure, it makes more sense to just go straight on through with the lowest point being the same all the way along the rocker. Further, Iím doing this in 16GA steel, which is nearly twice as thick as the original, so the extra strength (in spots) from nonsensically stamping pan shapes into it is completely pointless.

So to recap: the fix is about $140 in new steel from a repair panel guy, about $60 of steel from my place of work, three eight foot pieces with no more than three bends each per side, and a bunch of extra steel basically folded into a 3"x1" angle to patch in and curve up and down with the floor. I go in, use a chalk line to set two lines to cut, remove two sets of garbage with a drill (spot welds), fix the torque boxes that the rocker attaches to... and then just clean and start welding.

If I put drain holes in it the right places and paint each piece aside from the spot weld locations, it should never rust - itís zinc plated! As strong or stronger than original, right curve on the outside, and nobody but an expert will know.

JR1

> RamblinRover Luxury-Yacht

JR1

> RamblinRover Luxury-Yacht

10/08/2016 at 12:08 |

|

Sorry took a few days to reply. Had an exam this week so I was nose deep in books.

Thatís awesome you have a solid starting point for the Lincoln. And the parts are reasonable which is good as well. I imagine once that sheet metal is fixed youíll have climbed one of the biggest mountains with the Capri.

And trust me I know it looms. Not sure if it is the weight or what but something about being under that car is uncomfortable a bit.